Been a while since I've posted, been busy and all, but hope to get back into the swing of things ;) My E46 is now at 120k miles.

Anyway this story was from last October when the car had done about 108k miles, whilst I was on a 450 miles trip from London to Glasgow. A week or so before my departure I was doing some general checks under the bonnet, and I spotted something unusual with the mechanical belt tensioner which I had replaced about 20k miles earlier. I was pretty sure that it was meant to have a dust cap, as I could see the torx bolt underneath. I made a mental note to check realoem, but simply forgot before leaving for Glasgow.

So I was about 300+ miles into my trip on the highway to see the folks, when suddenly I saw the red battery light come on, my mind started to do the math, either it was alternator/battery issue, or it was the first sign of a belt/pulley issue (the other being a heavy steering, but I was driving straight as an arrow on the highway) . By the time my mind worked through this, perhaps 5 secs, I'd eased off the gas, but then the needle went straight from 12 'o'clock and into the red.

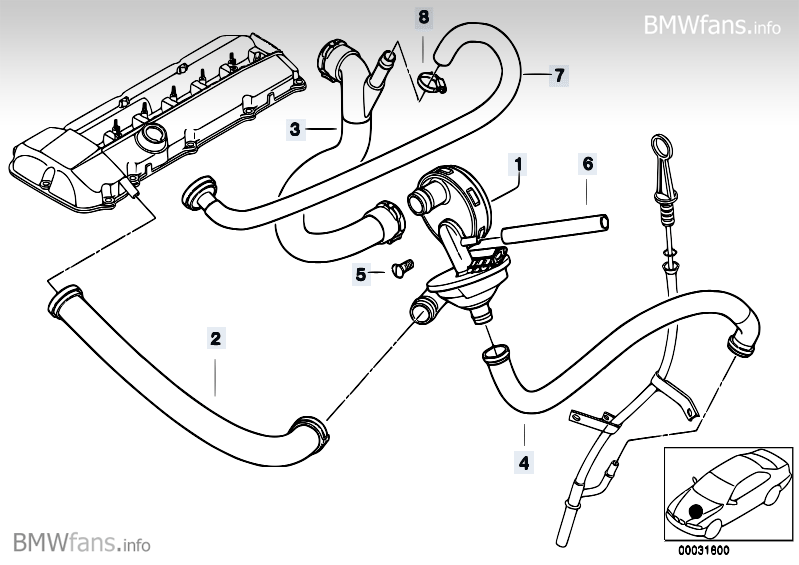

I pulled over straight away, connected up my bluetooth OBD tool and via a phone app thre coolant temp was reading 126 deg C (normal is 90-96)!! I opened the bonnet expecting to see a shattered water pump pulley, and torn belt, but instead it was the belt tensioner pulley that had lost its dust cap, had come off instead:

In fact the pulley had come off completely, weeks later I found it still on the engine under tray intact. But the next few pics will show where the failure occurred.

Initially I thought it was a freak failure, but then by the time the tow truck got me home and I removed what remained of the old tensioner the following day and I got a closer look, I realised what part the missing dust cap played. Here are pics of the failed tensioner:

Note in the first photo the black discolouration on the body of the tensioner, at the time I presumed this was from the (black) pulley literally disintegrating and exploding into the body of the tensioner. But like I mentioned, I found it intact on the engine under tray. I presume the discolouration is release of grease inside the tensioner?

But the most telling picture is the last one, which shows where that circular spring clip snapped. I presume that with the dust cap missing, water and dirt managed to work there way into the inner mechanism of the tensioner, an over time caused it to fail.

I installed new belts as well as replacing the tensioner. However the old belt look totally undamaged, but best not to take a chance. Instead I keep the old belts in the boot, in case of future emergency. And guess what? I now keep a spare set of dust caps in my glove box, and any time I open the bonnet to check the oil or fill the windscreen washer, I now have a glance down and check all dust caps are in place!!

On a side note, I was shocked at how quickly the temp needle shot into the red. Think about it, I wasn't haemorrhaging coolant. OK, so coolant wasn't flowing around the engine, but it was still in place around the engine. It would be reasonable to assume that in my case the needle would have gradually increased, but no such luck for us E46ers!

An lastly I was worried about potential cylinder head damage, as the we all know these M54 engines don't take too kindly to overheating. But I can report, that after a further 15k miles of driving (incl a return trip to Italy), all is well, no coolant use, no white smoke and no yellow sludge in the oil. I have recently bought a cylinder compression tester anyway, so will check compressions and post back here. I had a compression check down at about 60k miles, and as far as i can remember, all cylinders were around 160 psi +/- 4

Now we know the M54 engine can handle coolant going up to 126 deg C without warping the head, but that doesn't mean I want it to happen again!!! I hope this info about dust caps helps out and saves other E46 owners.